A Comprehensive Guide to Press-Fit Bottom Bracket Bearings: Unveiling the Realm of Precision Engineering

The realm of mountain biking has witnessed an unprecedented surge in technological advancements, with each innovation aimed at enhancing the rider’s experience. Among these cutting-edge developments, the advent of press-fit bottom bracket bearings has emerged as a game-changer, offering a seamless blend of performance, durability, and precision engineering.

The Evolution of Bottom Bracket Bearings

In the early days of mountain biking, threaded bottom brackets reigned supreme, providing a reliable and time-tested solution for attaching the crankset to the frame. However, as the sport evolved and demands for greater efficiency and weight reduction intensified, the industry sought innovative alternatives. Enter the press-fit bottom bracket, a revolutionary design that eschews threads in favor of a sleek, integrated system.

Understanding Press-Fit Technology

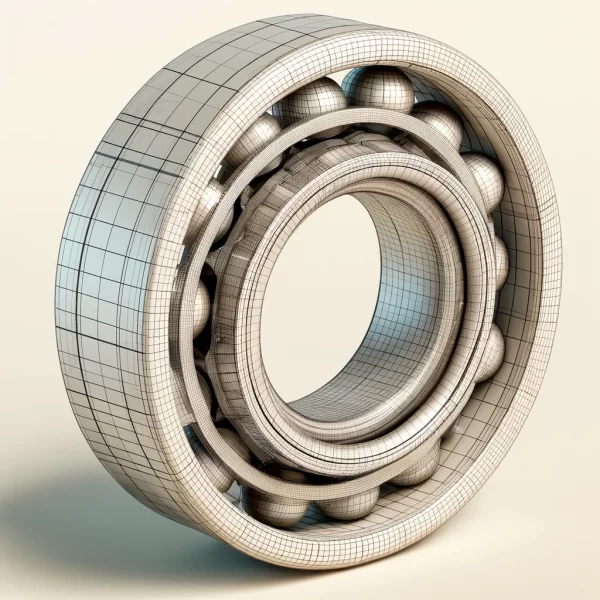

Press-fit bottom brackets, as the name suggests, rely on a precise interference fit between the bearings and the frame’s bottom bracket shell. Unlike their threaded counterparts, these bearings are literally pressed into the frame, creating a secure and virtually inseparable union. This design not only eliminates the need for a threaded metal sleeve, but it also facilitates the use of wider bottom bracket shells and larger frame tubes, enhancing pedaling stiffness and overall handling precision.

The Advantages of Press-Fit Bottom Brackets

The benefits of press-fit bottom brackets extend far beyond their sleek aesthetic appeal. Here are some of the key advantages that have propelled their adoption in the mountain biking world:

- Increased Stiffness: By allowing for wider bottom bracket shells and larger frame tubes, press-fit bearings enable a more direct transfer of pedaling forces, resulting in improved stiffness and enhanced power transfer.

- Weight Reduction: The absence of a threaded metal sleeve contributes to a noticeable weight reduction, a coveted attribute in the realm of performance-oriented mountain biking.

- Seamless Integration: Press-fit bearings seamlessly integrate with the frame, creating a clean and streamlined appearance that complements the modern aesthetic of high-end mountain bikes.

- Durability: When installed correctly, press-fit bearings offer exceptional durability, thanks to their secure interference fit and the ability to withstand the rigors of off-road riding.

Click here for Specialty Retro Products’ Press in Bottom Brackets for Gary Fisher and Kline Frames!

Installation and Maintenance Considerations

Proper installation and maintenance are crucial to ensure the longevity and optimal performance of press-fit bottom brackets. Here are some key considerations:

- Specialized Tools: Installing and removing press-fit bearings requires specialized tools, such as bearing pullers and press-fit tools, to ensure a precise and damage-free installation or removal process.

- Cleanliness: Maintaining a clean and debris-free bottom bracket area is essential to prevent premature wear and contamination of the bearings.

- Periodic Inspection: Regular inspections and timely bearing replacements are recommended to maintain the smooth operation and longevity of your press-fit bottom bracket system.

- Professional Assistance: For those who prefer professional assistance, seeking the expertise of a qualified bike mechanic can ensure a flawless installation and proper maintenance.

Exploring Performance Upgrades

As with any high-performance component, the world of press-fit bottom brackets offers a wealth of upgrade options to elevate your riding experience. From ceramic bearings that boast superior smoothness and longevity to specialized coatings that enhance corrosion resistance, the possibilities are endless.

Ceramic Bearings: The Pinnacle of Precision

Ceramic bearings have emerged as the epitome of performance and durability in the world of press-fit bottom brackets. These advanced bearings, crafted from ultra-smooth ceramic materials, offer several distinct advantages over their steel counterparts:

-

- Reduced Friction: Ceramic bearings exhibit significantly lower friction levels, resulting in a smoother and more efficient pedaling experience.

- Increased Longevity: The inherent hardness and corrosion resistance of ceramic materials contribute to an extended lifespan for these bearings, even under the most demanding conditions.

- Temperature Resilience: Ceramic bearings maintain their performance and integrity across a wide range of temperatures, making them suitable for all riding environments.

Specialized Coatings: Enhancing Durability

In addition to ceramic bearings, specialized coatings have become a popular choice for enhancing the durability and corrosion resistance of press-fit bottom brackets. These coatings, often applied to the bearing races and other components, offer superior protection against the elements and extend the lifespan of the bearings.

One notable example is the XD15 coating, a proprietary technology developed by industry leaders like Enduro Bearings. This advanced coating not only enhances corrosion resistance but also improves bearing smoothness, ensuring a seamless and efficient pedaling experience.

Stay tuned for Part Two of our comprehensive guide, where we’ll dive into the essential steps for replacing, repairing, and maintaining your press-fit bearings. Whether you’re dealing with a FatCity, Gary Fisher, or Kline bike, our next installment will provide you with the practical know-how to keep your ride smooth and efficient.

In the meantime, visit specialtyretroproducts.com for a wide selection of press-fit bearings tailored for your FatCity, Gary Fisher, and Kline bikes. Equip your ride with the best and get ready for an unparalleled biking experience!